Rogalla Antifriction Bearings

Antifriction bearings are what get the modern world moving. An industrialised society would not be possible or would not even have been able to develop in the first place, without the use of antifriction bearings, because the industrial production of goods would have been inconceivable.

The history of the antifriction bearing goes back a long way – archaeologists found small cylindrical pieces of wood near the wheel hubs of a chariot during excavations from the Celtic period. Like so much of human history, though, this was forgotten, and it was not until 1490 that Leonardo da Vinci drew the design of a ball bearing.

What we consider to be antifriction bearings today were developed in the late 19th century.

Antifriction bearings are components in which the friction resulting from the rolling motion of two components moving relative to each other is reduced by rolling elements.

This operating principle essentially distinguishes antifriction bearings from plain bearings, in which parts moving against each other are in direct contact

with each other or are only separated by a lubricating film.

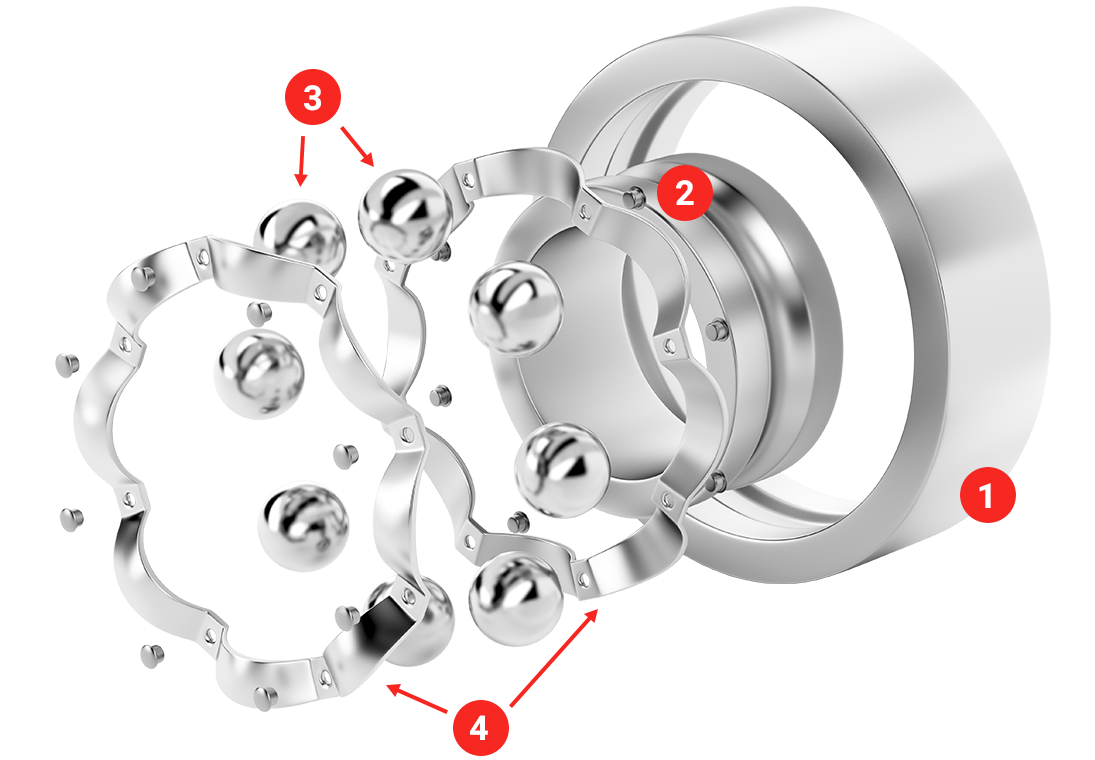

The basic design of an antifriction bearing is actually relatively simple and generally consists of the following components:

with integrated raceway for guiding the rolling elements

with integrated raceway for guiding the rolling elements

(balls, rollers or needles)

and guiding the rolling elements in the raceways

Illustration shows a riveted sheet steel cage

The direction of the main load leads to a differentiation between the two basic forms, namely radial bearings and thrust bearings.

Both basic forms of antifriction bearings are available as ball bearings and roller bearings.

absorb forces perpendicular to the shaft axis (radial).

absorb forces in the direction of the shaft axis (axial).

The basic forms of antifriction bearings are divided into a further six groups:

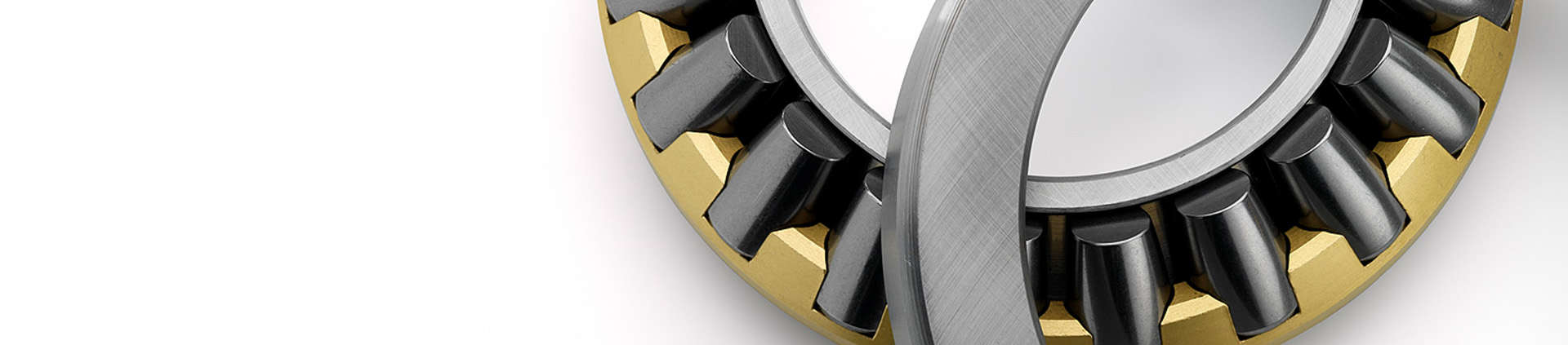

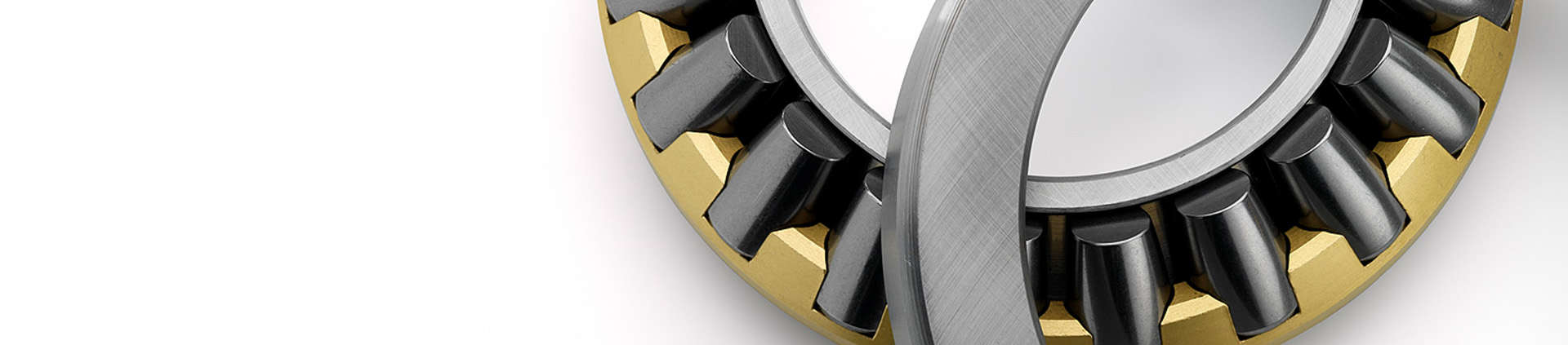

While ball bearings are particularly suitable for fast-turning applications due to the point contact between the balls and the raceway, they are less suitable for high loads. This is where roller bearings are used, as the line contact between the rollers and the raceway allows them to support very high forces.

The right antifriction bearing for every application. The characteristic properties of the various types predetermine the respective design for specific areas of application and uses. When installed, antifriction bearings are functionally relevant machine elements, and the choice of the suitable antifriction bearing is the decisive factor for service life and durability.

In most cases, the size of the adjacent structure provides the framework for the size of the antifriction bearing or limits the dimensions. However, installation space and the direction of the main load alone are not sufficient for an optimal selection of the suitable antifriction bearing.

Antifriction bearings perform their work, most of which is invisible or imperceptible to the user, in electric motors, gearboxes, fans, pumps, compressors, household appliances, drills and powered tools, construction machinery, cars and rail vehicles, conveyor systems, wind turbines, chemical and petrochemical plants, agricultural engineering, food industry and beverage production, raw materials extraction, iron and steel industry, paper industry and pulp processing, cement mills, plastics production and film manufacture, medical technology, aerospace technology and robotics and automation technology, to name just a few applications and industrial sectors.

Important selection factors include:

Today’s users have a wide range of standard antifriction bearings to choose from when looking for the right antifriction bearing for their particular application.

Antifriction Bearing Accessories

Spherical Plain Bearings & Rod End

Housing bearings & housing units