Slewing rings are versatile, large-diameter antifriction bearings that transmit axial and radial forces while at the same time absorbing the resulting tilting moments. Their high load-carrying capacity makes them ideally suited for applications involving high stresses.

Slewing rings are not considered ball or roller bearings since, unlike the latter, they are not mounted on a shaft or in a housing but are instead installed axially by screwing the bearing rings to the adjacent structure. Slewing rings are normally mounted in a horizontal position, but there are also applications and design forms where they are suspended or mounted vertically.

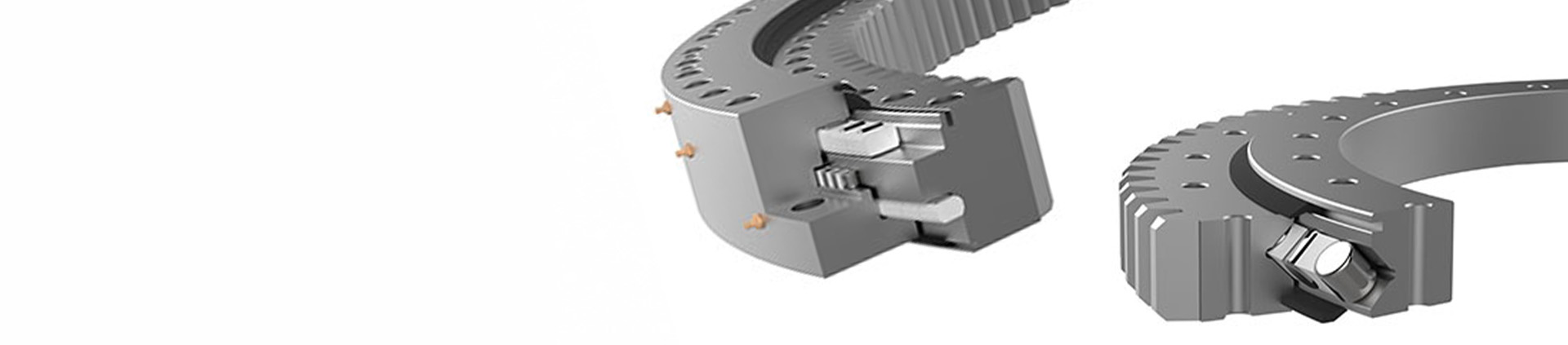

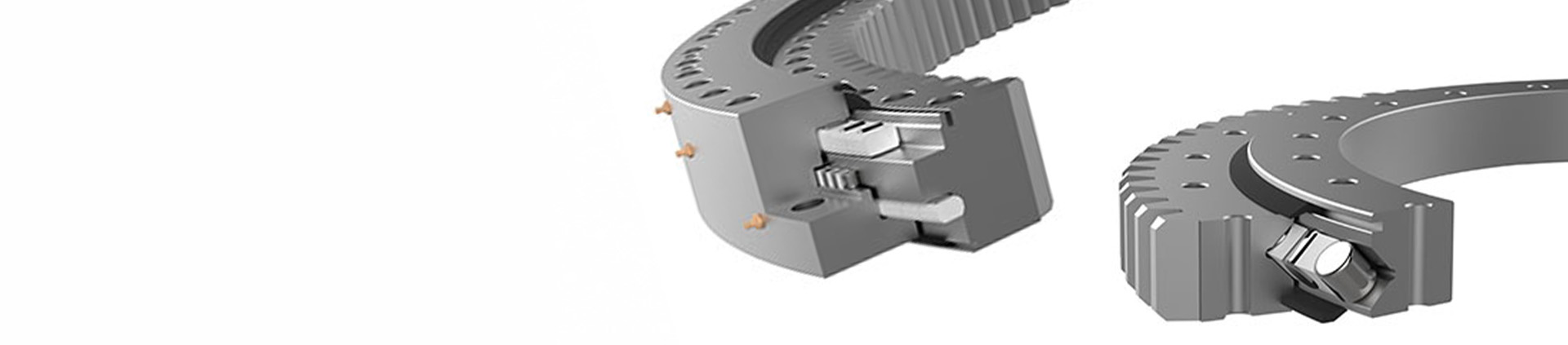

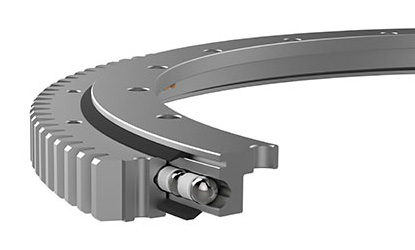

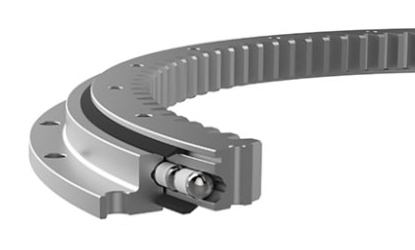

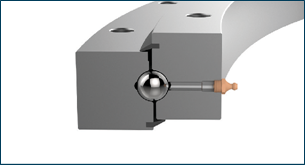

The basic structure of a slewing ring consists of one outer and one inner ring, in the case of single-row designs, and up to three rings in the case of multi-row designs, as well as rolling elements which are held at a distance and guided by spacers and a sealed raceway system with grease lubrication.

Slewing rings differ according to the shape of their rolling elements and the principle of power transmission, coming in the form of ball bearing slewing rings and roller bearing slewing rings. Special forms are also available.

Slewing rings are used as important connecting elements in many applications and a wide range of machines and systems, such as in:

to mention just a few.

Our product range includes slewing rings in dimensions from Ø 200 mm to Ø 5000 mm.

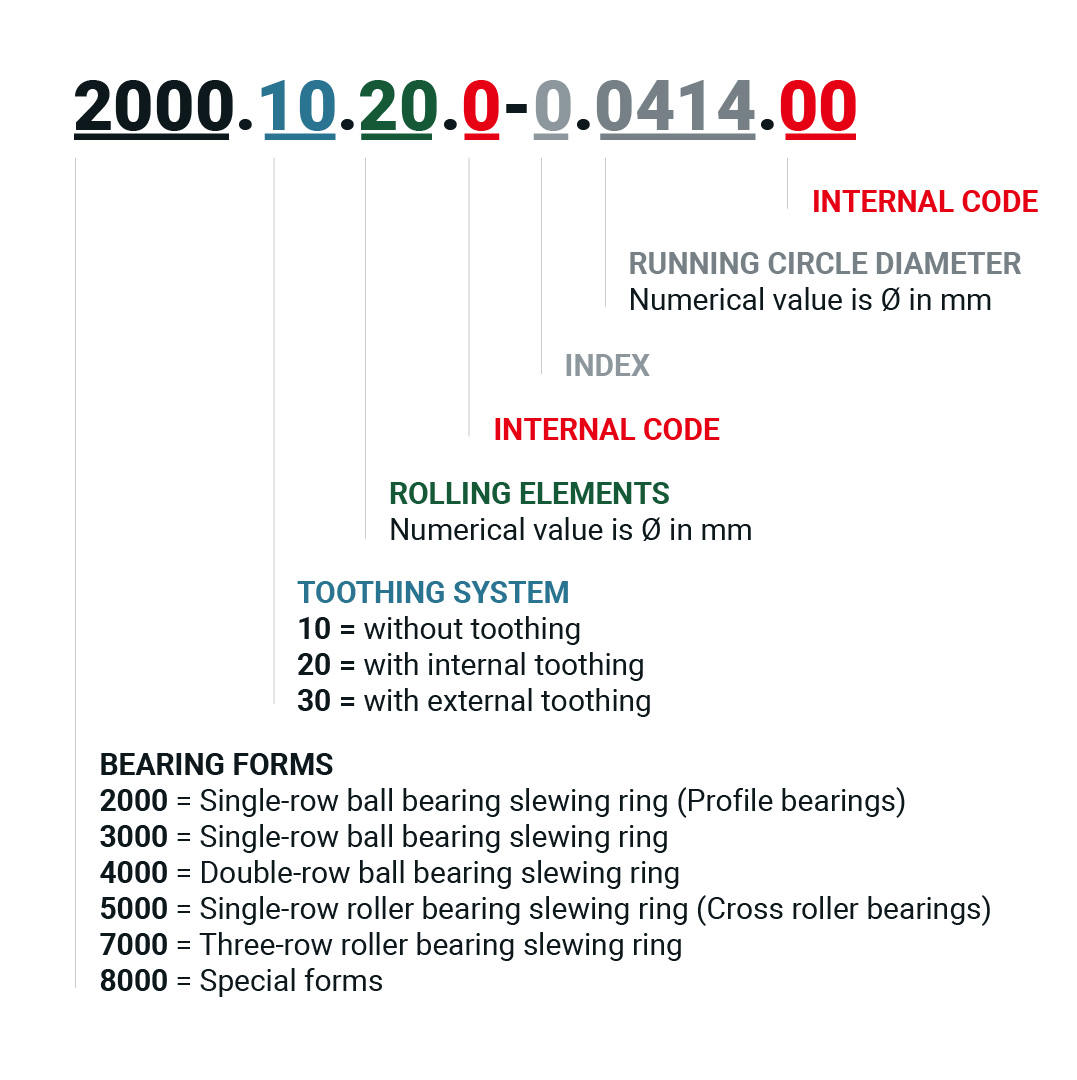

Series 2000 - Profile bearings (light series)

Series 3000 – Four-point bearings

Series 4000 - Eight-point bearings (double-axis bearing)

Series 5000 - Cross roller bearings

Series 7000 - Thrust radial roller bearings

Series 8000 - Special forms of slewing ring

Slewing rings are made of low-alloyed heat-treatable steels. Most of those used are seamlessly rolled rings made of C45+QT and 42CrMo4+QT according to EN 10083-2 and EN 10083-3 or 10083-3 with stricter requirements in order to guarantee a temperature application range of -20°C.

The following table shows the designations for the two most widely used slewing ring materials by country and their respective material number according to EN 10083-2:2006 and EN 10083-3:2006:

| COUNTRY | MATERIAL KEY | ||

| GERMANY | DIN | Ck45 | 42CrMo4 |

| ITALY | UNI | C45 | 42CrMo4 |

| SPAIN | UNE | C45K (F1140) | 42CrMo4 (F8232) |

| JAPAN | JIS | S45C | SNB7 |

| SCHWEDEN | SSSTAHL | 1672 | 2244 |

| USA | AISI | 16B45 | 4142 |

However, the use of other materials is possible for special applications or where there are particular functional requirements, such as use in very humid or salty environments.

In the case of ball bearing slewing rings, the rolling elements used as standard comply with DIN 5401; in the case of roller bearing slewing rings, cylindrical rollers conforming to DIN 5402 are used.

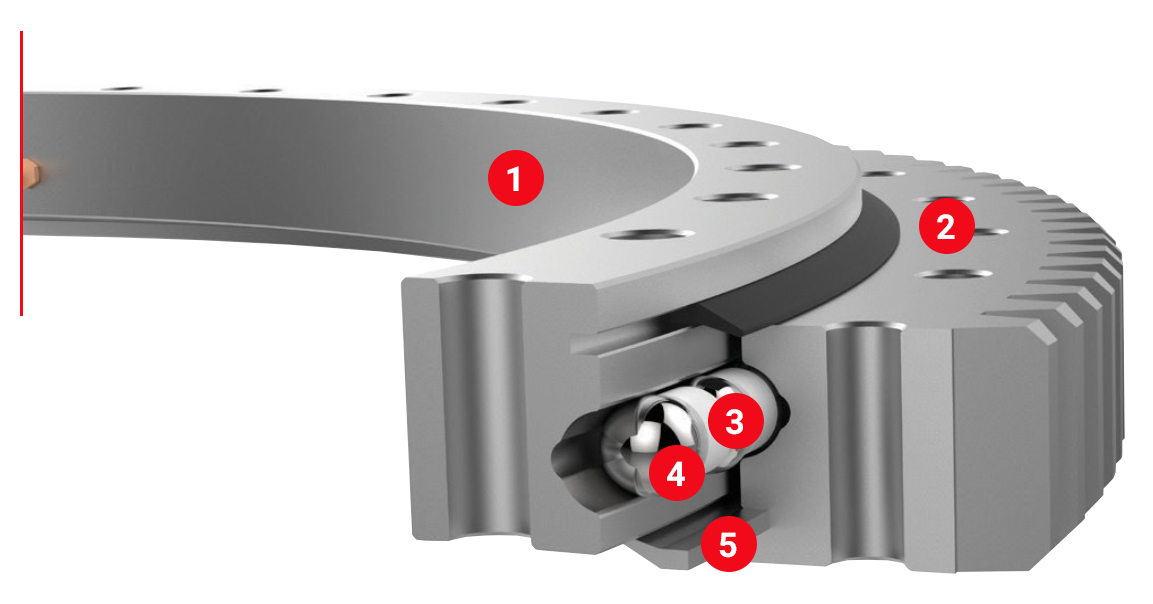

The elements used for rolling element separation (figures 1 to 5) are made of PA6, PA1010 or PVC, depending on the application and requirements.

Standard spacer version for ball bearing slewing rings

Band cage for ball bearing slewing rings

Axial roller spacer cage

Radial and axial roller spacers

Cross roller spacers

Slewing rings are generally designed with integral seals on both sides of the raceway system.

![Drehverbindungen / Dichtungssysteme [Translate to English:] Dichtungssysteme](/fileadmin/Produkte/Drehverbindungen/Drehverbindungen_Word/Dichtungssysteme.png)

Sealing systems

Special sealing profiles and arrangements, labyrinth or multiple systems are used for specific requirements in difficult ambient conditions or in the case of mechanical stresses.

In addition, however, there are various applications and cases in closed drive systems where sealing is not required on one or both sides and the raceways are supplied and lubricated via the oil circuit of the system.

ROTIS standard slewing rings are equipped with a lubrication system for lubricating the raceway systems.

Other versions of the lubrication system such as axial arrangements of the lubrication holes, alternative sizes and shapes of lubrication nipples or threads are possible. If the customer requires the slewing rings to be supplied without grease nipples, the lubrication holes are closed using standard plastic plugs.

The lubricant industry offers a wide range of special lubricants for specific applications and uses in adverse ambient conditions. The suitable lubricant is determined in accordance with the respective performance requirement.

The general tolerances of the standard slewing rings conform to ISO 286-1 and ISO 286-2.

For applications with higher accuracy requirements, such as industrial robots, medical diagnostic and magnetic resonance therapy equipment, radar systems, etc., narrower tolerances and a higher degree of quality can be achieved.

A variety of options for protecting the machined metal surfaces from corrosion are available, depending on the requirements and ambient conditions.

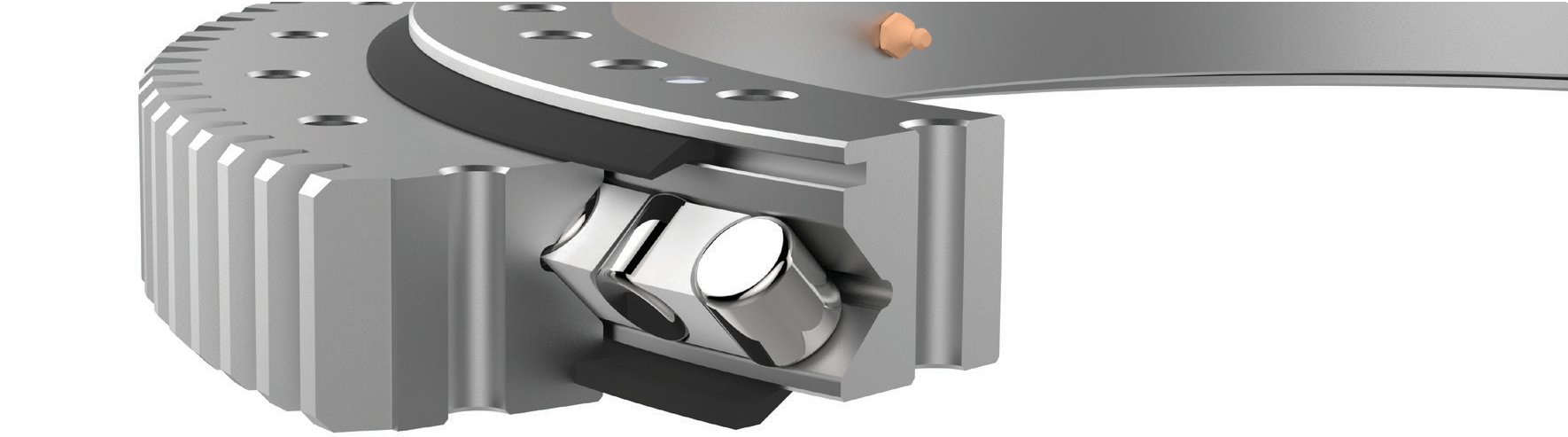

The rolling elements, which in this construction take the form of balls, describe the principle of power transmission (point contact) and give the bearing its name..

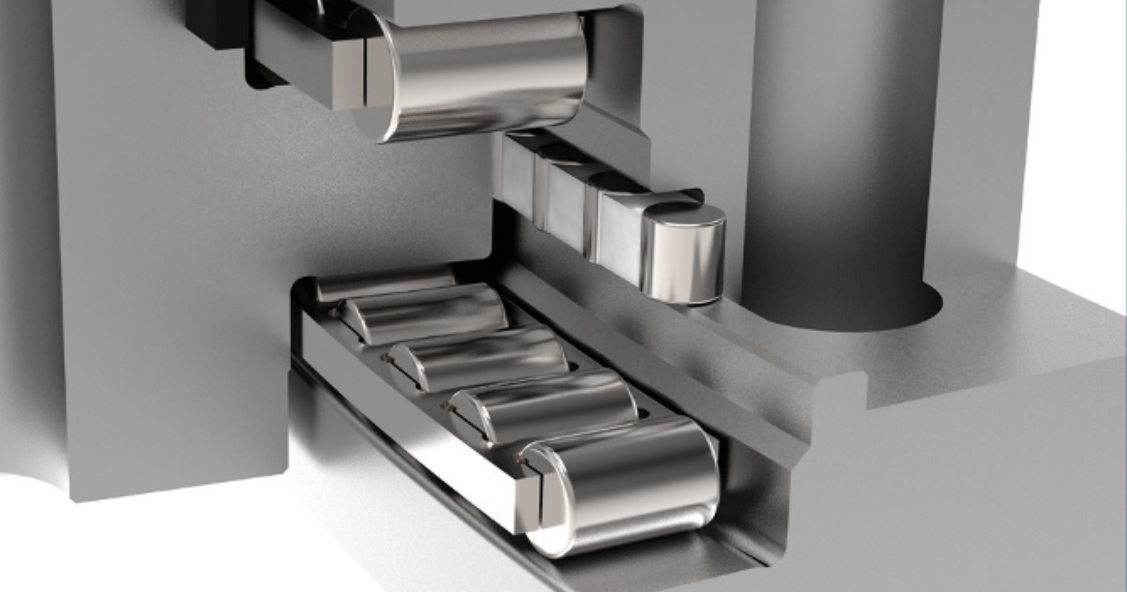

The rolling elements, which in this construction form cylindrical rollers, describe the principle of power transmission (line contact) and give the bearing its name.

In addition to the classic main constructions, there is a wide range of special forms for specific uses and applications.

All specifications and designations apply exclusively to slewing rings from the manufacturer ROTIS. Please note that the product specifications and features mentioned may deviate due to product changes and are therefore non-binding. The desired product specifications and features must therefore be expressly agreed in each individual case at the time of purchase.

* Castrol, Rustilo, and the Castrol logo are trademarks or registered trademarks of Castrol Limited (a BP Europa SE company and part of BP p.l.c.) or an affiliate of BP p.l.c.

** Shell, Gadus, and the Shell logo are trademarks or registered trademarks of Royal Dutch Shell plc, or an affiliate of Royal Dutch Shell plc.

*** Mobil, Mobilith and the Pegasus Design are trademarks or registered trademarks of Exxon Mobil Corporation or an affiliate of Exxon Mobil Corporation.

**** The Tectyl® trademark and all rights are owned by Ashland Consumer Markets (Valvoline™) or an affiliate of Ashland Global Holdings Inc.